MCH-100-AB: BATTERY POWERED HEAT GUN AND SOLDERING KIT

MCH-100-AB: BATTERY POWERED HEAT GUN AND SOLDERING KIT

NSN: 4940-01-571-5371 NSN: 4940-01-578-3961

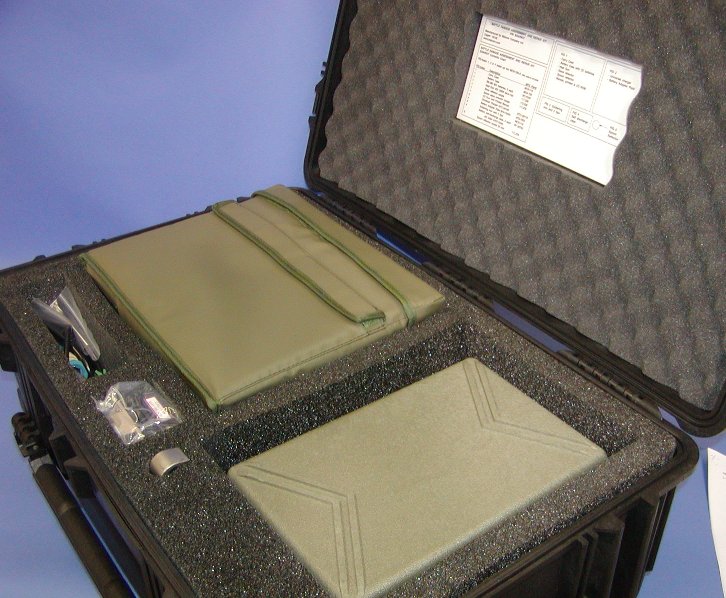

Includes:

- Power Supply (MCH-102NW)

- Two (2) Batteries (BT-70790)

- 325 watt Heat Gun (111.038.1)

- Three (3) interchangeable nozzles for shrinking and soldering

- 13mm Sieve Reflector Nozzle (111.476)

- 16mm Spoon Reflector Nozzle (112.028)

- 20mm Spoon Reflector Nozzle (111.478).

- 50 watt Soldering Iron w/ three (3) interchangeable tips (MCH-116 Kit)

- Carry Bag w/ heat resistant pouches (MCH-110)

- Pelican Hard Plastic Transportation Case (1650-BDAR)

- Battery Charger (BTC-70819)

Temperature Capabilities

500F to 950F (depending on nozzle, heating element). Temperature ramp-up from ambient conditions is 60-90 seconds with a continuous run time of 30-35 minutes depending on ambient environmental conditions.

Soldering Capabilities

The MCH-116 is a 50 watt soldering iron powered by the MCH-102NW 48VDC Power Supply and includes three interchangeable tips.

Power Supply

The Heat Gun is powered by the MCH-102NW Power Supply that utilizes two standard Department of Defense BB-390B/U Nickel Metal Hydride smart batteries capable for redeployment within 2 hours of simultaneous charging using the kit included multi-voltage input BTC-70819 SPC Lite Fast Charging System. The Power Supply is stored in the MCH-110 Carry Bag, which includes two (2) heat resistant pouches to store hot tools, and allows maintainers to carry the 17 lb Heat Gun Kit to the work site.

Standards & Testing

Tested to perform in Harsh Environments, the MCH-100-A exceeds Military Standard Requirements for use in explosive atmospheres, zero electromagnetic interference environments, and in robust handling battle deployment situations, the MCH-100-A is the only tool in its class approved for use on fueled aircraft by NAVAIR; eliminating the need for an auxiliary power unit, power cable spreads and open flames on flight decks during avionics repairs.

· MIL-STD-461E EMI Control, RE101

· MIL-STD-810F Environmental Tests

- 511.4 Explosive Atmosphere

- 506.4 Rain Intrusion

- 509.4 Salt Fog

- 516.5 Shock

Product Development History

The US Army Battle Damage Assessment and Repair Team at Redstone Arsenal required a portable electric repair kit to rapidly return disabled equipment by applying field-expedient repairs to damaged electronics, components, wiring, and cables in the field. Malcom responded with a combination repair kit that included the MCH-100-A, developed as a portable, handheld, robust, powerful, and adaptable convective heat tool to repair avionics in harsh wind, rain, salt-fog, desert, arctic, explosive atmosphere, and electromagnetically sensitive environments, and the MCH-116 Battery Powered Soldering Iron developed as a heavy-duty accessory to the MCH-100-A delivered in a robust transportation case.

In general, BDAR restores the minimum essential combat capabilities necessary to support a specific combat mission or to enable the equipment to self-recover. BDAR is accomplished by a creative "work with what you have" approach and typically involves bypassing components or safety devices, the cannibalizing or controlled exchange of parts from like or lower priority equipment, fabricating repair parts, jury-rigging systems, taking shortcuts to standard maintenance, and using substitute fluids, materials or components. Battle Damage Electrical Repairs require the ability to solder and desolder as well as apply heat shrink to insulate installed electronics in harsh field conditions. The MCH-100-AB allows BDAR teams to rapidly restore mission critical electrical capabilities. NSN: 4940-01-571-5371

LINKS & FILE DOWNLOADS:

MCH-100-AB Itemized Components List

VIEW ON GSA STORE

APPLICATIONS

Shrink Tubing, Soldering

INDUSTRIES

Aerospace, Aviation, Electronics

CUSTOMERS

U.S. DOD

PARTNER(S)

Leister, Bren-Tronics, Fieldtex, J & J technologies, Skydyne

VIEW/DOWNLOAD

MCH-100-A Specifications

Parts & Accessories

You Tube: Battery Management Procedures

Contact us to discuss application challenges and technical requirements. Call 1-800-289-7505 or complete our online form.